Anti-Carbonation Coating

What is Anti Carbonation?

It is the process of chemical weathering by which minerals containing soda, lime, potash are other basic oxides are changed to carbonates by the action of Carbon dioxide and water.

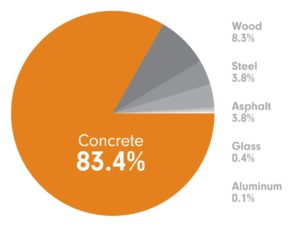

In today world, concrete is the most used material / product in construction industry. Concrete structures exposed to atmospheric carbon dioxide emitted from various sources, in presence of moisture / water and as describe in the above reaction, atmospheric carbon dioxide diffuses slowly through the concrete and the process of carbonation is initiated, the pH of concrete slowly turns acidic and starts rusting the reinforcing steel bars.

Once concrete is rusting, concrete starts spalls and falls-off leaving an open passage for contaminants to easy penetrate in to the matrix of the concrete.

Once concrete is rusting, concrete starts spalls and falls-off leaving an open passage for contaminants to easy penetrate in to the matrix of the concrete.

Anti-carbonation coatings are surface treatments that have a high resistance to carbon dioxide. They protect concrete from carbonation by acting as a carbon dioxide barrier. But prior to the application of coating, it is very important to study the failure pattern and consider other product for repair treatment.

How to repair and maintain the affected concrete?

Prior to the application of coating, all weak, damaged, spalled concrete shall be removed in defined pattern, clean the surface of concrete and exposed reinforcement bars. Apply EP 410, anti-corrosive paint, fill / re-surface the concrete removed surface using B 33, high build, polymer modified cementitious renovation mortar.

If the concrete is still at the initial stage of the carbonation affect, concrete shows up the cracks. At this stage, it is recommended to treat the cracks using SU 10, single component, polyurethane joint sealant (PU Sealant).

ARDEX ENDURA, provides range of Concrete repair products, waterproofing coating products. One the best anti-carbonation coating, AC 20, Anti-Carbonation Façade Protective Coating.

ARDEX ENDURA ACADEMY

Our industry, like any other, requires on-going training to keep up with the changes in legislation/standards and materials. Our purpose-built training facility enables us to offer a range of demonstrations and seminars that can be tailored to your specific needs, ensuring total confidence in the specification and subsequent on-site application. The academy allows you to learn about new technologies including ‘Industry best practices for Tiling, Waterproofing, Concrete Repair and Flooring’ along with Technical guidance and product information.

For the latest and most up to date information and advice, visit the ARDEXENDURAacademy centres across India (Bangalore, Mumbai, Ahmedabad, Delhi, etc.,). For Waterproofing Contractors and applicators committed to providing a high level of workmanship, ARDEX ENDURA helps them to increase both their professionalism and productivity.