Slurry Bond for Flooring Tiles

ARDEX ENDURA

23 Oct 2024

04 Mins

Tiles cannot be stuck to the concrete floor directly with proprietary tile adhesive as the flatness is not assured while the slab is poured. So, invariably you will need to create an additional base with sand and mortar to obtain a flat levelled surface for fixing the tiles.

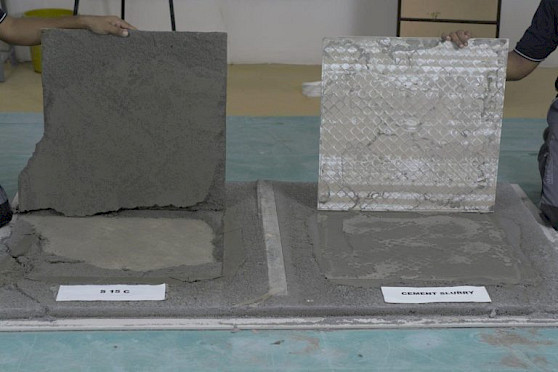

Cement slurry has been conventionally used for fixing floor tiles. Cement is mixed with water to obtain a honey-like consistency and this slurry is spread on the freshly laid CM screed and tiles fixed tamping with a wooden or rubber mallet.

This methodology of installing floor tiles is well suited for Ceramic Tiles due to its porous body. Ceramic tile is made from clay and sand and a ceramic coating on the surface. The porous structure of the ceramic tile is sufficient for the cement gel to create a mechanical bond with the substrate and tile.

With technological advancements, vitrified tiles have gained popularity as it offers plenty of benefits over a ceramic tile. They are more durable and scratch resistant, consistent in size, shades and thickness. Also, Vitrified tiles have very less water absorption as they have very low porosity. Vitrified tiles are manufactured through a process called ‘vitrification’ which gives them their low porosity. This low porosity inhibits the ‘mechanical’ key bonding of the tile to the substrate and could result in debonded/loose tiles.

To overcome these problems, instead of the traditional cement paste, it is recommended to use a polymer modified slurry adhesive, in slurry form as a ‘wet-on-wet’ application over the fresh laid screed. This will ensure a strong bond between the screed and the vitrified tiles.

Advantages

- Fast and efficient – has long open time enabling larger spread areas

- Non-shrink adhesive

- Easy to use, only mix with water

- Better bonding strength

- Can be grouted within 24 hours without waiting for the moisture to evaporate

S 15 C is a polymer modified, high strength, grey cement-based adhesive used in slurry consistency for fixing vitrified tiles, ceramic tiles and stable natural stone installation.

S 15 C, mixed to a soft, wet slurry consistency is applied with a flat side of a trowel over the plastic, semi-dry mortar bed. The slurry is usually just 1 mm – 2 mm thick. The tiles are placed in the wet slurry and “beat-in” with a rubber mallet

Key features are:

- Longer working time compared to cement slurry

- Economical: Suitable for tiling on fresh screed

Suitable for vitrified tile installation, ceramic tile installation and stable natural stone installation.

ARDEX ENDURA ACADEMY

Our industry, like any other, requires on-going training to keep up with the changes in legislation/standards and materials. Our purpose-built training facility enables us to offer a range of demonstrations and seminars that can be tailored to your specific needs, ensuring total confidence in the specification and subsequent on-site application. The academy allows you to learn about new technologies including ‘Industry best practices for Tiling, Waterproofing, Concrete Repair and Flooring’ along with Technical guidance and product information.

For the latest and most up to date information and advice, visit the ARDEXENDURAacademy centres across India (Bangalore, Mumbai, Ahmedabad, Delhi, etc.,). For Tiling Contractors and applicators committed to providing a high level of workmanship, ARDEX ENDURA helps them to increase both their professionalism and productivity.